Produtos / Products

COGENERATION

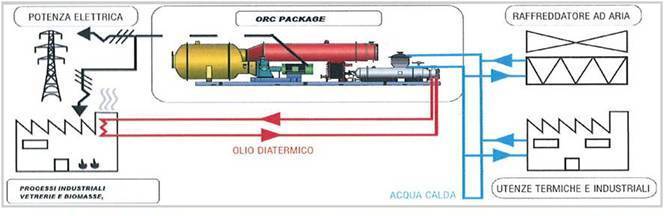

Thermal oil circuits are generally used to recover large amounts of heat from the flow of gas emitted during work processes. The heat exchanger usually passes the fume emission line to minimize/eliminate the impact of the heat recovery system on the primary processes.

The hot thermal oil produced by the thermal oil exchanger feeds an ORC turbo generator that converts the heat energy into electrical energy and heat at a low temperature.

TRIGENERATION

Heat energy as the hot water from ORC generator can be used to produce cooling capacity. This is possible by connecting of absorption system, to produce chilled water for air conditioning and various industrial processes where cooling is required

Applications:

- Glass Industries

- Paper Industries

- Textiles Industries (dye-works, etc.)

- Brick-works Industries: (furnaces, ceramics, cement products..)

- Chemical Industries

- Plastic Industries (molding and injection of plastic materials)

POLLUTION CONTROL (FILTRATION)

BDF Energy offers up to date Bag filters with Sleeves technology, SCR (Selective Cathalitic Reduction), as well as up to date CCCT (Catalytic Ceramic Cartridges Technology) instead of standard SCR equipments for Nox abatement.

All of them ready or directly combined with energy cogeneration plant. This combination, with the adoption of innovative diathermy solutions, allows the use of the waste fumes before filtration, greatly limiting the expensive ESP (electrostatic systems), thus shifting the cost of a major investment for the Company to an opportunity for energy costs reduction and energy production.

POLLUTION CONTROL Automation

BDF Energy with MRC Systems has extensive experience in the most critical point of filtration: the automation between furnaces and filtration systems.

For all other equipment BDF ENERGY offers the opportunity of integrated solutions, whatever is the applied anti pollution equipment.

POWER MANAGEMENT, AUTOMATION AND PROCESS CONTROL

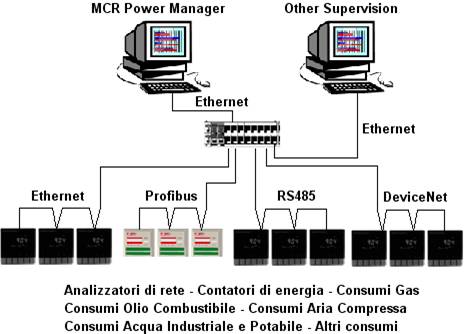

Thanks to many years’ experience in the field and in-depth knowledge of the production processes, BDF Energy is able to handle data flows and power consumption in order to get Saving By Monitoring.

MCR SYSTEMS and TDE MACNO can touch-on and meet the various needs of single production sites: from field and control room instruments to control devices, and from single production machines to complete plants, utilities and additional services, up to lights network supervision.

BDF ENERGY POWER MANAGEMENT PACK offers a variety of solutions of tailor-made hardware and software for command and control systems:

- MES systems and ERP connection, factory networks

- Energy Recovery: Active Front End or DC Bus supply

- Development and creation of basic firmware

- Design and customization of PLC, SCADA and DCS system software

Contacto

Metaglobal, Ldª

ricardo.moreira@metaglobal.pt - geral@metaglobal.pt

Rua João Morais Barbora nº11, Loja A1600-416 Lisboa

Portugal

00351 217 158 553